Kukho iintlobo ezininziukuphosa, ngokwesiqhelo zahlulwe zibe:

① ukubunjwa kwesanti eqhelekileyo, kuquka ukungunda kwesanti emanzi, ukungunda kwesanti eyomileyo kunye nokuqina kwemichiza kokungunda kwesanti.

② ngokwezinto zokubumba, ukuphosa okukhethekileyo kunokwahlulwa kube ziindidi ezimbini: ukuphosa okukhethekileyo ngesanti yamaminerali kunye nelitye njengeyona nto iphambili yokubumba (njengotyalo-mali, ukubunjwa kodaka, ukubunjwa kwegobolondo kwi-workshop yokuphosa, ukuphosa uxinzelelo olubi, ukubunjwa okupheleleyo, ukubunjwa kwe-ceramic, njl. ukuphoswa koxinzelelo oluphantsi, ukuphosa kwe-centrifugal, njl.).

Inkqubo yokuphosa idla ngokubandakanya:

① Ukulungiswa kokubumba (isikhongozelo sokwenza isinyithi elulwelo sibe yintsimbi eqinileyo). I-mold casting inokwahlulwa ibe ngundo lwesanti, i-metal mold, i-ceramic mold, i-mold yodongwe, i-graphite i-mold, njl njl ngokwezinto ezisetyenzisiweyo, kwaye inokwahlulwa ibe ngumbumba olahlayo, i-semi isigxina kunye nokubumba okusisigxina ngokwenani lamaxesha okusetyenziswa. Umgangatho wokulungiswa kokubumba yinto ephambili echaphazela umgangatho we-castings;

② ukunyibilika kunye nokugalelwa kwesinyithi. Iintsimbi ezityhidiweyo (i-alloys) zibandakanya ikakhulu isinyithi, intsimbi kunye ne-alloys non-ferrous cast;

③ ukunyangwa kunye nokuhlolwa kokulahlwa, kubandakanywa ukususwa kwemicimbi yangaphandle kumbindi kunye nomphezulu wokulahlwa, ukususwa kwesango kunye nesikhuphukeli, ukutshixwa kunye nokusila i-burr, i-burring kunye nezinye iiprotrusions, kunye nonyango lobushushu, ukubunjwa, unyango lothintelo lomhlwa kunye nomatshini orhabaxa.

Inkqubo yokuphosa inokwahlulwa ibe ngamacandelo amathathu asisiseko, oko kukuthi, ukulungiswa kwesinyithi, ukulungiswa komngundo kunye nokuphosa unyango. Intsimbi yokuphosa ibhekisa kwizinto zentsimbi ezisetyenziselwa ukuphosa kwimveliso yokuphosa. I-alloy eyenziwe yinto yentsimbi njengeyona nto iphambili kunye nezinye izinto zetsimbi okanye ezingezizo. Ngokuqhelekileyo ibizwa ngokuba yi-cast alloy, ingakumbi ibandakanya isinyithi esityhidiweyo, intsimbi etyhidiweyo kunye ne-alloy non-ferrous alloy.

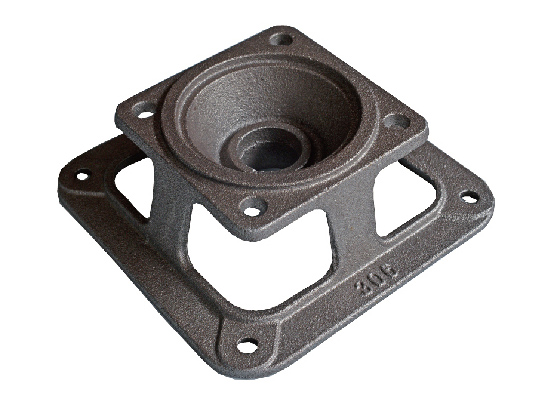

JN-FBOUkudubula kweSanti ethe nkqo, Ukubumba kunye nokwahlulwa okuthe tye ngaphandle kweUmatshini wokuBumba ibhokisiyeemveliso ze-JUNENG zineenzuzo zokudutyulwa kwesanti ethe nkqo, ukubumba kunye nokwahlula okuthe tye. Kukulungele kakhulu ukuvelisa ii-castings ezahlukeneyo. Ngokwezinto ezityhidiweyo ezinobude obuhlukeneyo bokubumba kwesanti, inokulungelelaniswa ngokulandelelana kwaye ngokungenasiphelo ukuphakama kwesanti yokudubula kwi-molds yesanti ephezulu kunye nesezantsi, ukugcina inani lesanti esetyenzisiweyo, ngoko ukunciphisa iindleko zemveliso.

Abahlobo abanesidingo banokubonisana neenkcukacha ezifanelekileyo zomatshini ngokusebenzisa le ngcaciso yoqhagamshelwano ilandelayo.

Umphathi weNtengiso : zoe

E-mail : zoe@junengmachine.com

Umnxeba : +86 13030998585

Ixesha lokuposa: Mar-11-2025